One Point Energy Solutions

Incepted in the year 2021, “ONE POINT ENERGY SOLUTIONS” is a distinguished retrofit solutions provider. Immensely acclaimed in the industry owing to their preciseness, these services are presented by us in standard forms to our clients.

Our proprietary expertise and combination of latest engineering technology with specifically designed software, makes us a Complete Solutions Provider and enables us to offer Integrated Controls over traditional Air Handling Units

Our Values

Integrity First

We promise honesty and transparency. We uphold the highest standards of integrity and honor the commitments we make.

Customer Driven

We win when our customers win. Our long-term strategic relationships provide unique insights and the ability to deliver exceptional customer experiences and solutions.

Purpose Led

We believe in doing well by doing good and hold ourselves accountable to make the world a better place through the solutions we provide, our engagement in society, the way we do business, and our commitment to protect people and the environment.

Future Focused

Our culture of innovation and continuous improvement drives us to solve today’s challenges while constantly asking ‘what’s next.’

Understanding The EC technology

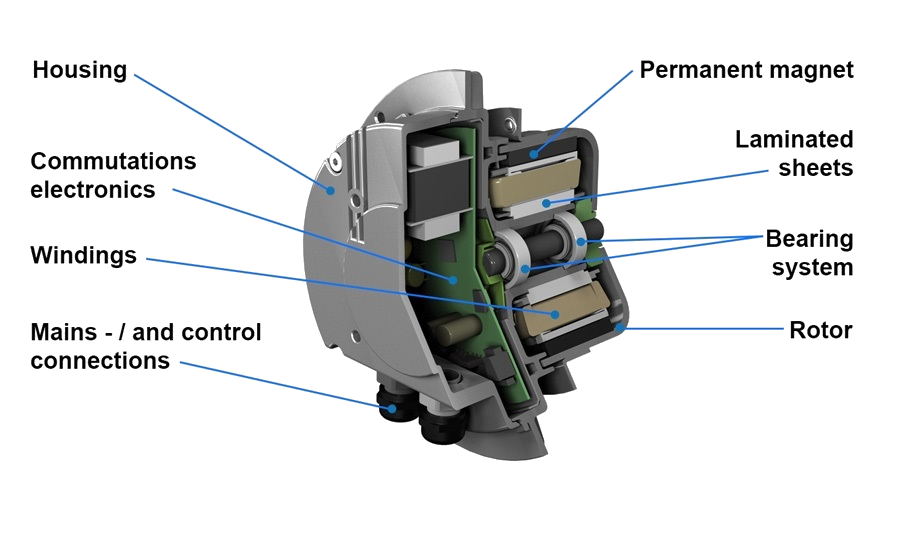

The EC-motor (EC = Electronically Commutated) is an inverter-fed synchronous motor with permanent magnets in external rotor construction. The motor position is dependent upon voltage supplied via an inverter module (similar to the principle of a frequency inverter). The EC commutation electronics are different from a frequency inverter in that they decide how the motor phases in the stator are supplied with current (commutation) depending on position, rotation direction and default.

Permanent magnets in the rotor produce a magnetic field which is required for full load production. A high efficiency, low noise, and continuous motor speed control is possible with this. An assembly flange on the rotor is used for impeller assembly. Depending on the motor type, a terminal box is available with cable screw connections or connection cable for easy and quick connection. Depending on the application area is possible to adopt further control functions (e.g., constant pressure control, volume flow control, temperature control, air quality control)

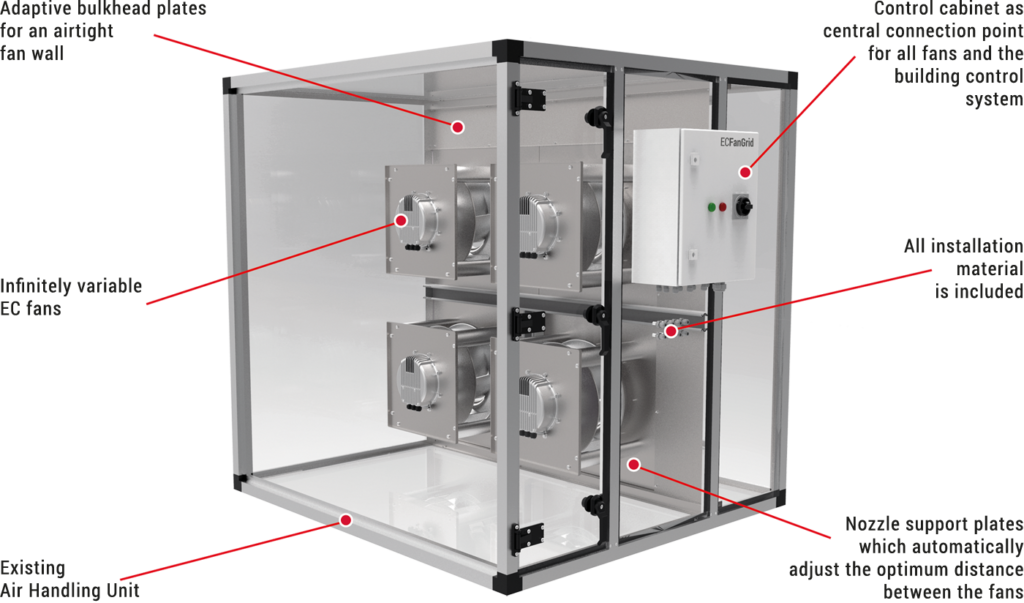

What is an EC Fan Wall?

An ECFanWall consists of several EC fans operated in parallel. The volume flow multiplies in proportion to the number of fans, with constant pressure conditions. The EC fans used are not only highly efficient, as a perfectly coordinated unit (electronics, motor & impeller) they enable simple plug & play solutions for almost every ventilation requirement.

Furthermore, several controllable fans can be adapted much better to the air output actually required, which increases efficiency at every operating point.

The ECFanWall retrofit system is particularly suitable for replacing old, inefficient, belt-driven fans in ventilation units. It does not matter which make is used. The retrofit system is flexible and always suitable!

Why Retrofitting?

Outdated fans are one of the main causes of excessive energy consumption in existing air conditioning systems. Modern, energy-efficient fans, on the other hand, easily achieve system efficiencies of 70%. The more efficient components enable electricity savings of up to 50%

The ECFanGrid is ideal for retrofitting existing air conditioning units, especially when a single large radial fan is to be replaced. Due to its smaller component size, the ECFanGrid can be brought into the building and installed by one or two people through standard doors

In contrast to a conventional belt drive fan, which covers a relatively large floor area, the ECFanGrid is completely floor-free. This means that maintaining hygiene within the air handling unit is more effective. No dust is released into the supply air as there is no longer any belt abrasion.

Due to its “built-in” redundancy, the ECFanGrid offers an absolute level of reliability. In the unlikely event that a fan should fail, only this part of the air flow is lost. The loss of this air flow is then automatically compensated for by increasing the speed of all the other fans.

About the product

The energy saving EC-motors are developed and manufactured in Germany. Through the combination of know-how and innovative manufacturing technology we attain a quality that meets the highest standards.

Quality pays for itself. The slightly higher investment costs compared to conventional motors is usually amortized within a short operating time due to lower energy consumption and greater ease of installation (no transformer controller, motor overload switch, thermocouple meter, VFD, or phase angle controller are necessary).

Advantages:

Products in our kitty

Sectors Covered

Get In Touch With Us

Better yet, see us in person!

We love our customers, so feel free to visit during normal business hours.

One Point Energy Solutions

AQ – 5 – 22, BPTP Parklands, Sector 81,

Faridabad, Haryana- 121004

mohit@onepointenergy.in

amit@onepointenergy.in

9643388032

9996800501

Feel Free To Connect

We love our customers, we will advise you free of charge and without obligation so feel free to contact us for any enquiry

AQ – 5 – 22, BPTP Parklands, Sector 81, Faridabad, Haryana- 121004

Copyright © 2021 One Point Energy Solutions – All Rights Reserved.

Designed by – MDS Automech Solutions