EC technology

As a forward-thinking company, we identified long ago that a sensible processing of energy is of crucial ecological and economic significance – particularly with regard to CO2 emissions and rising energy prices.

Therefore our engineers and technicians are constantly working to improve the energy efficiency of our products – and with success: Our motors with modern EC technology are more than 90% efficient and save up to 50% in energy as opposed to conventional motor technology. The low energy consumption not only contributes towards protecting the environment but at the same time also reduces our customers’ operating costs.

EC technology is much more than an ”energy efficient wonder“. EC motors are maintenance free and silent. The integrated, intelligent controller allows a continuous control and further additional functions like pressure, volume flow, or air quality control. Our EC products fulfil the strictest requirements when it comes to energy efficiency, cost effectiveness and high air quality.

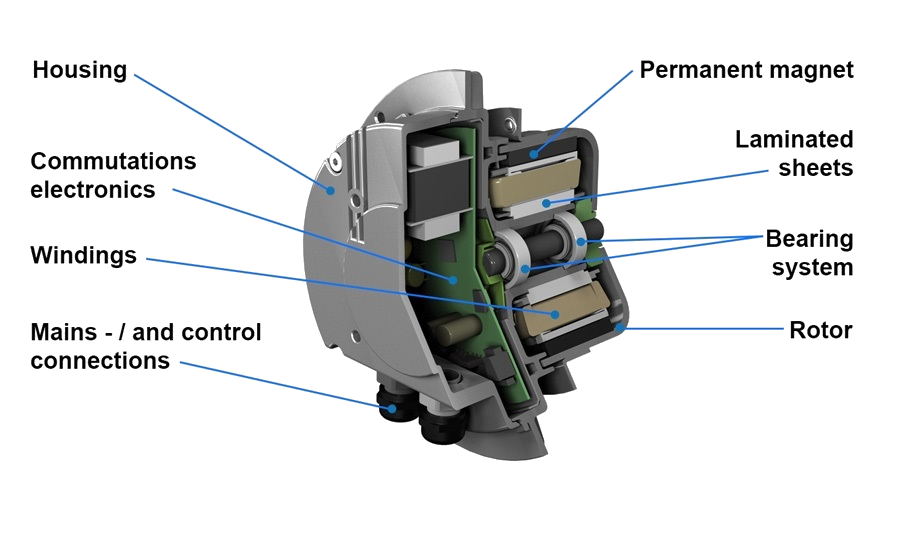

Understanding The EC technology

The EC-motor (EC = Electronically Commutated) is an inverter-fed synchronous motor with permanent magnets in external rotor construction. The motor position is dependent upon voltage supplied via an inverter module (similar to the principle of a frequency inverter). The EC commutation electronics are different from a frequency inverter in that they decide how the motor phases in the stator are supplied with current (commutation) depending on position, rotation direction and default.

Permanent magnets in the rotor produce a magnetic field which is required for full load production. A high efficiency, low noise, and continuous motor speed control is possible with this. An assembly flange on the rotor is used for impeller assembly. Depending on the motor type, a terminal box is available with cable screw connections or connection cable for easy and quick connection. Depending on the application area is possible to adopt further control functions (e.g., constant pressure control, volume flow control, temperature control, air quality control)

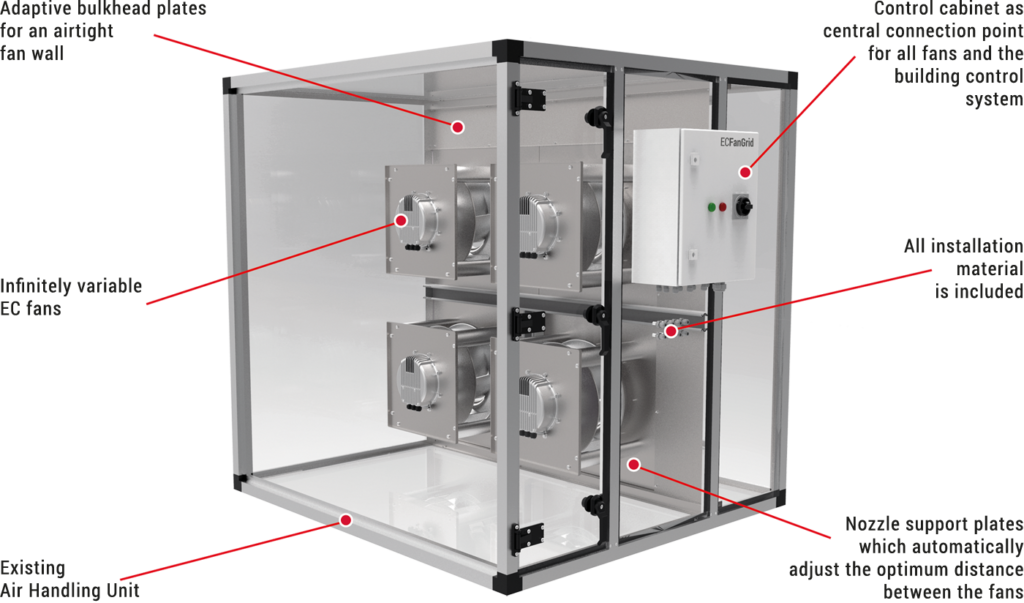

What is an EC Fan Wall?

An ECFanWall consists of several EC fans operated in parallel. The volume flow multiplies in proportion to the number of fans, with constant pressure conditions. The EC fans used are not only highly efficient, as a perfectly coordinated unit (electronics, motor & impeller) they enable simple plug & play solutions for almost every ventilation requirement.

Furthermore, several controllable fans can be adapted much better to the air output actually required, which increases efficiency at every operating point.

The ECFanWall retrofit system is particularly suitable for replacing old, inefficient, belt-driven fans in ventilation units. It does not matter which make is used. The retrofit system is flexible and always suitable!

Feel Free To Connect

We love our customers, we will advise you free of charge and without obligation so feel free to contact us for any enquiry

AQ – 5 – 22, BPTP Parklands, Sector 81, Faridabad, Haryana- 121004

Copyright © 2021 One Point Energy Solutions – All Rights Reserved.

Designed by – MDS Automech Solutions